|

Grid Making

by Hall, Hartwieg and Nguyen

doi:10.3908/wormatlas.9.13

Overview

Although there are several new custom-produced films now in use for the collection of thin sections, we always use either Pioloform or Formvar. Pioloform films are somewhat stronger and generally do not need to be reinforced with a carbon coat. Both films are suitable for use with either slot grids or mesh grids.

Formvar

Formvar-coated grids can be purchased from outside vendors, but we have found that better quality grids can be made in the laboratory. We usually purchase Formvar as a 1% solution, dissolved in ethylene dichloride. Kept in a stoppered glass bottle, Formvar solutions remain stable for months. However, with repeated use they tend to degrade, probably due to addition of trace amounts of water. If you are seeing small holes in your freshly made films when viewed on the electron microscope, it is time to open a fresh bottle of Formvar. Formvar films are not very stable unless coated with a thin layer of carbon using a vacuum evaporator device, as we describe below.

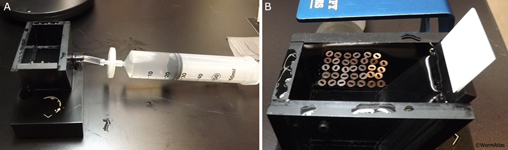

We have found the EMS Film Casting Device and the Smith Grid Coating Trough (EMGridmakingFIG 1) to be useful in this procedure. Alternately, the Formvar solution can be poured into a clean wide-mouth bottle or Coplin jar.

EMGridmakingFIG 1 EMGridmakingFIG 1

Glass microscope slides are first rinsed in toluene, cleaned with a Kimwipe until shiny and dry, then dipped into the Formvar solution. As the slide is withdrawn slowly from the solution, fumes from the solution will bathe the slide in solvent, allowing excess Formvar to drain back into the main volume. This allows a thinner Formvar coating to be created on the slide. After drying the coated slide for a minute, a razor blade is used to score the top and bottom edges of the film on each side of the slide. Then breathe gently on the slide to release the film before dipping the slide vertically into a water bath filled with distilled water. A Formvar film should float off the slide from each side, to float two films on the surface of the water bath. Use a #5 forceps to place clean grids onto the floating Formvar film, dull side down, avoiding any portion of the film that shows holes, wrinkles or bright colors. Clean another glass slide with ethanol and allow the slide to dry. Smoothly dip the slide onto the floating film with grids from above, then lift away from the water. Allow the slide to dry thoroughly in a petri dish and keep covered until ready to carbon coat. Alternately, floating films with grids can be picked up using a sheet of Parafilm rather than a glass slide. Carbon coating should be done as soon as possible to stabilize the film before it begins to sag (within 2-12 hrs).

Specialized equipment is required to do the carbon-coat. We use a Denton evaporator (vintage 1970) (EMGridmakingFIG 2), but newer devices are now available from EM supply houses.

EMGridmakingFIG 2 EMGridmakingFIG 2

It can be difficult to measure the amount of carbon being deposited onto the slide in fact if you can see the carbon buildup through the bell jar on the evaporator, you may have already added too much. The optimal thickness of carbon is so thin that it is barely detectable by eye. We try to evaporate carbon from sharpened carbon rods in about ten short bursts (several seconds each), or in one longer burst. After carbon is added to the Formvar film, the film is slightly brittle when poked with a forceps. Store coated grids on a covered petri plate until use at the microtome.

Once stabilized with carbon, a coated grid is very stable, and one can wait for months before its use. To pick up one grid from the coated slide, scratch carefully around the edge of the grid to detach it from the rest of the slide, being careful not to tear the film where it covers the opening on the grid.

Pioloform

Pioloform can be bought as a powder, prepared as a 0.5% solution in chloroform,

and stored in a wide mouth stoppered bottle. Clean a Gold Seal glass slide with

Ross lens tissue and dip the clean slide three fourth of the way into the bottle of the

Pioloform solution. Film thickness depends on the speed at which the slide is

removed from the solution. Drain excess fluid onto the side of the bottle. Allow

film to dry for 1 min.

To float the film, score the edge of one side of the glass slide on bottom (sawing

motion with a single edge razor blade) and on both sides of slide using a razor blade

to scrape on edge of film, but not scraping the corner of slide (no glass particles,

please). You will see some of the Pioloform film pile up as a ragged edge at edge of

the slide.

Breathe on the glass slide to release the film, and then dip slowly into a tank filled

with distilled water; the slide should enter at a shallow angle to release the film. Use

tweezers to gently pull film away from slide. Then, turn the slide over, score the film

on the opposite side, and release that film onto the surface of the water tank by the

same means.

If dissatisfied with the film thickness, one can experiment with the speed of slide

withdrawal from the Pioloform bottle. Alternately, add more powder to thicken the

Pioloform solution or add more chloroform to thin it.

Carefully place clean slot grids or mesh grids face down onto the films while they

are floating. Then move several films close together and pick them up with a fresh

piece of Parafilm. Store-coated grids on this Parafilm in a closed Petri plate to keep

clean. Alternately, each floating piece of Pioloform + grids can be picked up onto a

clean glass slide.

Helpful Hints

Slot grids are coated with Formvar or Pioloform on the dull side,

which makes it easier to collect serial sections onto the slot on the shiny side of the

grid (cf. Hall, 1995).

For immunocytochemistry, nickel mesh grids may be coated on either side, after

which plastic sections are collected on the same side for antibody treatments.

Equipment

EMS Film Casting Device (EMS, catalog #71305) is useful for making a uniform film of Formvar or Pioloform on a microscope slide. Directions for its use are available on the EMS website.

Smith Grid Coating Trough (Ladd Research, catalog #10840) (EMGridmakingFIG 1) is useful for floating good films of Pioloform or Formvar without fingerprints or dust. This gives a much better view of the film’s color, by which one judges the thickness of the film. It comes with a syringe mechanism for adjusting the water level inside the trough.

Figures

Click pictures for new window with figure and legend, click again for high resolution image

EMGridmakingFIG 1: Pioloform film casting trough. A. Pioloform film casting trough, side view. Syringe is used to supply distilled water to the trough, even while plastic films float on the surface. A lamp is positioned overhead (not shown) to help view the floating film. B. Pioloform film casting trough, top view. A thin plastic film on the waters surface has been loaded with copper slot grids. This film (virtually invisible here) will next be collected from the top with a clean glass slide to capture the grids onto the slide, covered by the plastic film. This assemblage will be allowed to dry before placing into the Denton evaporator for a carbon coat (see EMGridmakingFIG 2). Click pictures for new window with figure and legend, click again for high resolution image

EMGridmakingFIG 1: Pioloform film casting trough. A. Pioloform film casting trough, side view. Syringe is used to supply distilled water to the trough, even while plastic films float on the surface. A lamp is positioned overhead (not shown) to help view the floating film. B. Pioloform film casting trough, top view. A thin plastic film on the waters surface has been loaded with copper slot grids. This film (virtually invisible here) will next be collected from the top with a clean glass slide to capture the grids onto the slide, covered by the plastic film. This assemblage will be allowed to dry before placing into the Denton evaporator for a carbon coat (see EMGridmakingFIG 2).

EMGridmakingFIG 2: Denton carbon evaporator. This machine is commonly used for carbon-coating Formvar or Pioloform grids prior to section pickup, or for coating Kapton tape after ATUM sectioning (see ATUM methods section). The added carbon layer serves to strengthen Formvar or Pioloform films, and can also shield thin sections on Kapton tape from later contamination.

References

Hall, D.H. 1995. Electron microscopy and three-dimensional image reconstruction. Methods Cell Biol. 48: 395-436. Abstract

Hall, D.H., Hartweig, E. and Nguyen, K.C.Q. 2012. Modern electron microscopy methods for C. elegans. Methods Cell Biol. 107: 93-149. Abstract

|